| X, Y and Z controllers are 2A per phase. Schematic taken from "304 Circuits" book. |  |

| Here is my general setup. In up, there is oscilloscope which is very handy thing when analyzing steps generated by PC or by controllers. A small laptop PC runs EMC and small 32A variable voltage (2-16V) power supply feeds all of my electronics. |  |

|

|

| From side of machine. There are Y axel feeds, they are made from 14mm metal tube. Against that there is nylon rings fitted to be tight enough. In every feed, there is "oval" sanding in one end that by rotating feed-tube I can eliminate small misalignments. When I found right place for feeding, I just tighten the nut and it stays put. |  |

| The working area is 270mm x 360mm. |  |

| From front. There is also a box containing all the electronics. And if you look close enough, you will notice one of our cat's nose is coming to picture from right ;-) |  |

| Z axel has a small teflon/nylon rings attached to 6mm metal tube acting as feeder. Different types of hand drills maybe connected to this part, it's only matter of making suitable adapter for them... |  |

| Every motor (VEXTA 2-phase 1.8 degrees, 4V) is attached to holder with "hexagonal" screws. |  |

| Holder is a aluminium "tube" cutted to right lenght and drilled with proper holes to make axis go through and to fit motor. Holder also has 2 screws for attaching to machine itself, and these screwsholes are loose enough to allow proper adjustement to align axis to motor shaft. The motor shaft and screw axels are attached with rubber tube tightened with "water pipe tighteners". This allows small movements and eliminates vibrations translating to axel. |  |

| Every axel moves with small brass part which is attached to moving part. |

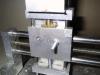

Here is my new control box. It's made from old NMT450 phone aluminium case. There is 30 pin cable between the box and the machine. Motors are attached with D9 connectors to part that changes three D9 connectors to 30 pin flat-cable connector.

15.4.2001. This is my new sound-damping case for machine. It has sound

dampening foam (30 mm) that is used in automotives and boats. There will be

plexiglass window in front of setup. It will be put on rubber-feets also to

reduce vibration sounds. Maybe there must be some sort of lightsource inside

also.

In the picture above there is joystick I bought from local "second-hand shop" for

10 mk (about $1.5). I'm thinking about controlling EMC with it for small

millings. It would be nice to mill small D9 or D25 holes with it. Or small

holes to boards or anything that doesn't need to be super accurate.

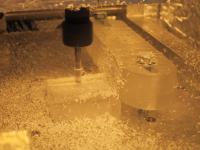

30.4-2.5.2001

I have got quite a nice pieces of plastic, and I'm milling

parts from it. It seems to do job quite well. I also got plastic window for my

sound dampenig case, and now it's really quiet.